Traditional manufacturing, rich in history

As experts in this industry, we know that the quality and character of handmade bricks cannot be achieved through mass production.

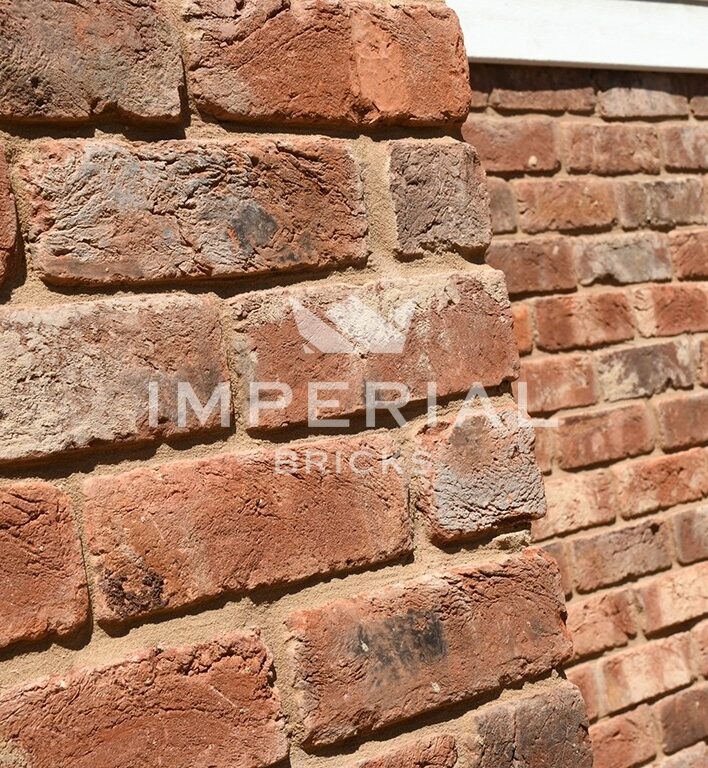

We thrive on the little imperfections that are created during our manufacturing processes which make our bricks truly unique.

Our manufacturing techniques perfectly replicate those used through the centuries; we strive for all our bricks to reach the same level of quality and appearance.